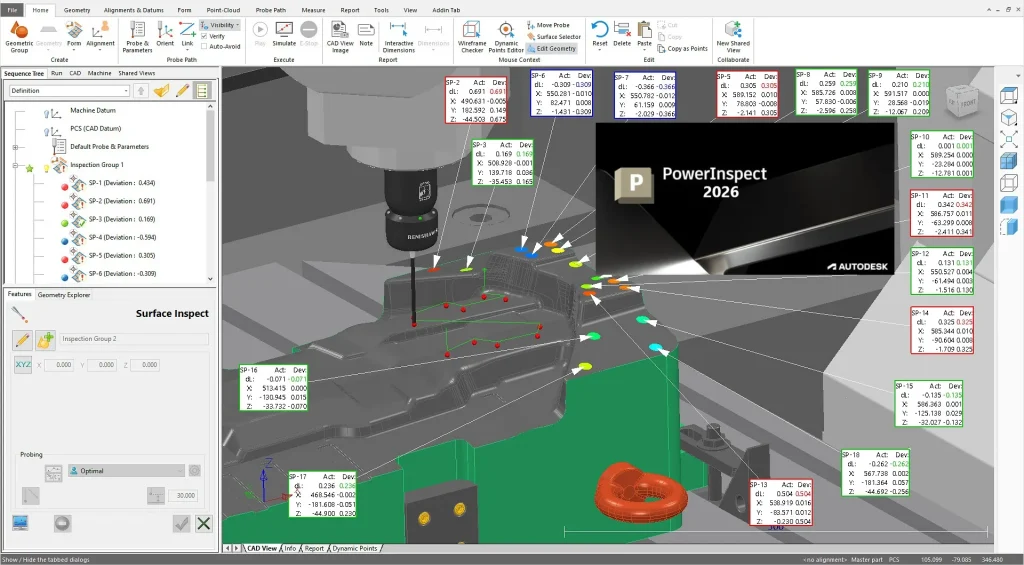

Autodesk PowerInspect Ultimate is a cutting-edge 3D measuring and inspection program for precise quality control and metrology applications. It is commonly employed in production situations where precision, repeatability, and adherence to technical specifications are essential. It allows users to measure, inspect, validate, and report on complex parts using a variety of measurement equipment.

The purpose of Autodesk PowerInspect Ultimate

The primary purpose of Autodesk PowerInspect Ultimate is to guarantee that manufactured parts adhere to design intent and engineering tolerances. The program enables inspection throughout the product’s lifecycle, from initial inspection to in-process verification and final quality assurance.

The key objectives include:

- Verifying the dimensional accuracy of manufactured components

- Minimise waste, rework, and manufacturing errors.

- Increase quality, consistency, and process reliability.

- Supporting industry regulations and quality requirements.

- Provide traceable and repeatable inspection results.

- PowerInspect Ultimate bridges the gap between CAD design and physical production by comparing actual measurements to digital models.

Complete features of Autodesk PowerInspect Ultimate

- Comprehensive measurement capability.

- Supports both touch and non-contact measuring methods.

- Measure points, curves, surfaces, holes, grooves, and freeform geometries.

- Conducting two- and three-dimensional inspections

- Capability to conduct manual, semi-automatic, and fully automated inspection operations.

- Wide Hardware Compatibility

- Compatible with coordinate measuring machines (CMMs)

- Support for portable measuring arms.

- Using laser trackers and integrating with structured light scanners.

- Supports exploration systems and optical measurement devices.

- CAD-based examination.

- Directly import 3D CAD models.

- Ability to compare measured data with nominal CAD geometry.

- Support for Geometric Dimensioning and Tolerancing (GD&T) examination

- Identify deviations, form flaws, and alignment issues.

- Advanced Alignment and Analysis

- Flexible alignment approaches (data-driven, best-fit, RPS, and custom alignments).

- Surface deviation and colour map analysis.

- Form, profile, and position analysis

- Trend analysis for process monitoring.

- Automation and Efficiency

- Automated inspection procedures for repetitive activities

- Reusable inspection templates

- Offline programming using CAD models.

- Reduce machine downtime with thoughtful inspection planning.

- Reports and Documentation

- Customizable inspection reports

- Presenting graphical and tabular results

- Colour deviation maps and a tolerance summary.

- Exportable reports for quality and traceability audits.

- Support for industry documents and compliance requirements

- Reverse engineering and verification support.

- Assist in assessing scan data versus design intent.

- Help identify design variations and production issues.

- Support for inspecting ancient parts without the original drawings.

- User Interface and Usability

- The graphical user interface is intuitive.

- A clear representation of measurement data

- Designed for both shop-floor and quality-control laboratory environments, this inspection tool provides interactive feedback.

Autodesk PowerInspect Ultimate is a powerful and flexible inspection solution for modern manufacturing and quality assurance environments. The program combines CAD-based inspection, extensive hardware compatibility, automation, and powerful analytics capabilities to help manufacturers achieve high levels of accuracy, consistency, and trust in their manufacturing processes. Its adaptability across a wide range of inspection scenarios—from manual inspection to fully automated scanning—makes it an indispensable tool for enterprises focused on quality, efficiency, and continuous improvement.